ROCHEM® FS Module

FS /FLAT SHEET OPEN CHANNEL for MF, UF, RO, NF-FILTRATION since 1994, improved 2015 MBR APPROVED SYSTEM IMO 340.549

MODULE DESCRIPTION

ROCHEM® FS Modules have especially been developed for Ultrafiltration (UF) applications to separate bacteria, viruses and fine solids from water and wastewater with a high fouling potential. The most important characteristic of the module is the low specific energy consumption at high and steady state flux rates.

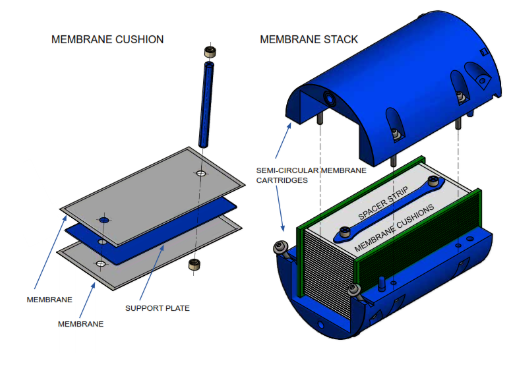

Central part of the ROCHEM® FS Module is the membrane cushion consisting of one support plate and two membranes.

Advanced ultrasonic welding and fully automated production guarantees perfect sealing of the cushions.

The membrane cushions combined with the customizable spacer strips are stacked inside two patented semi circular cartridges.

The typical FS Module contains up to 10 membrane stacks.

The cartridges are placed in series in a pressure vessel thus allowing a straight feed flow.

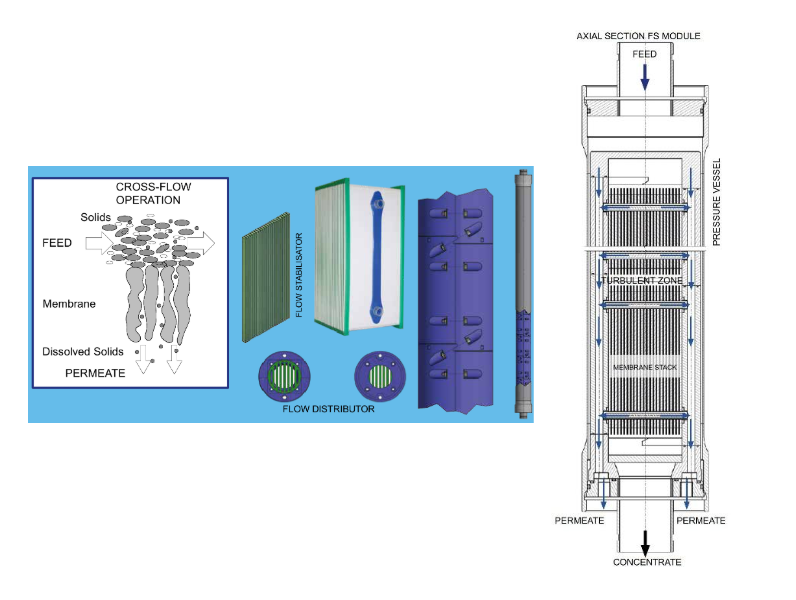

WATER FLOW INSIDE THE MODULE

The feed water is pressurized and sent to the FS Module. The feed passes through the open channel created by the spacers parallel to the membrane surface. Filtration takes place in orthogonal direction to the feed flow, this creates the cross flow operation as shown in the diagram below. Pure water permeates through the membrane cushion and is then directed into the permeate channel of the cartridge half case. The membrane cushion permeate outlets are sealed from the feed by the spacer strips. The pure water then exits the module through the permeate hose connectors. The section drawing shows the flow through the membrane cushions.