ROCHEM® Reverse Osmosis System – Navies

High reliability proven by 25 Navies worldwide

Since 1982, Rochem Group companies have been successfully designing and manufacturing seawater reverse osmosis (RO) desalination systems throughout the world.

About 1000 of Rochem RO plants are operational worldwide on naval units. Over 200 were installed on Italian Navy vessels such as destroyer, frigates, minehunters, submarines, supply vessels etc.

With a high degree of expertise in the marine industry and our own in-house engineering, fabrication, assembly and test facilities, we are able to offer high specification water treatment solutions and after-sales service.

Rochem’ seawater RO desalination systems are available in a wide range of capacities and can be custom-built to any required capacity.

Rochem RO systems are designed to fulfil all Naval requirements,such as:

- Shock-and vibration resistance

- EMC

- Airborne noise emission

- A-magnetic design, etc

according to NATO STANAG regulations.

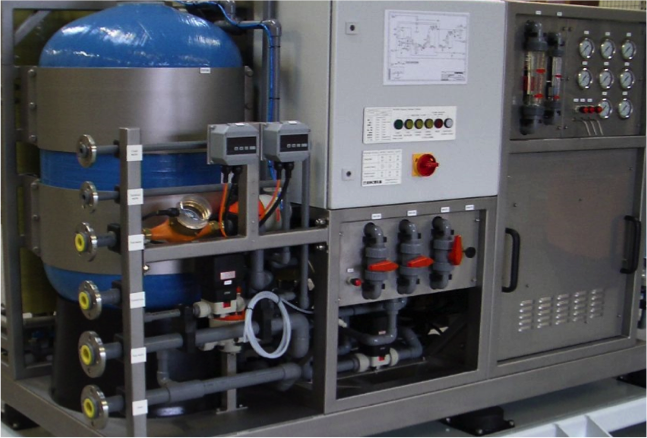

ROCHEM RO-Freshwater Generator

SYSTEM Type RO 1530-TS-35S

Capacity: 35 m3/day Fully automatic version with seawater preheating system

Characteristics of the ROCHEM RO Desalination plants

- Skid/frame assemblies of welded construction, in stainless steel AISI 316. For long life and minimal maintenance

- RO plants are automatically flow/pressure regulated. This allows the plant always to provide the maximum capacity achievable with the given feed water temperature/salinity at any given time

- PF Modules are repairable

- Exchange modules are available

- Long membrane life

- Low chemical products cost. Chemicals are only used for membrane cleaning, as there is no need for chemical treatment of the feed water

- All units are equipped with a fail safe system which protects them from potentially damaging external conditions and/or operator errors

- High pressure pumps start operation in optimum conditions because pressure builds up very progressively as the motorized pressure control valve closes slowly until it reaches its pre-determined stable position, corresponding to the set pressure in the modules

- At each normal system shut-down, all sea water wetted components will be rinsed with permeate thanks to the fully automatic “Stop & Rinse” mode. This will prevent any organic matter based fouling process developing during shut-down periods of up to 2 weeks, without the need for chemical disinfection

ROCHEM RO-Freshwater Generator

SYSTEM TYPE RO1020 PF4_PF1

Capacity: 20 m³ / day potable water plus partly 200 l/d technical water

fitted in Italian Navy FREMM Frigates

Design and Construction Standards

The ROCHEM RO Fresh Water Generators are designed, fabricated and approved according to the following National and International Standards:

- DIN – (German Industrial Standard)

- VDE – (Association of German Electricians)

- VDMA – (Organisation of German Mechanical Engineers)

- IEC – International Electric Standards for Electr. Motors

- ISO – International Standards

- NATO-Stanag BV 043(85) Shock-resistance

- NATO-Stanag BV 044(87) Vibration-resistance

- NATO-Stanag BV 0120 rev. 03/86 Electromagnetic Compatibility (EMC)

- BV 3000-2, rev. 02/91 E-Plants, planning and general directives

- BV 3100 E-Plants

- BV 3300, rev. 06/90 E-Plants, switch cabinets, switches

- BV 3400, rev. 03/88 E-Plants, cabling

The ROCHEM RO units are designed and constructed to fulfil the requirements of the following Classification societies:

- Germanischer Lloyd

- Lloyds Register of Shipping

- American Bureau of Shipping

- Det Norske Veritas

- Bureau Veritas

- RINA Certificates for high pressure hoses