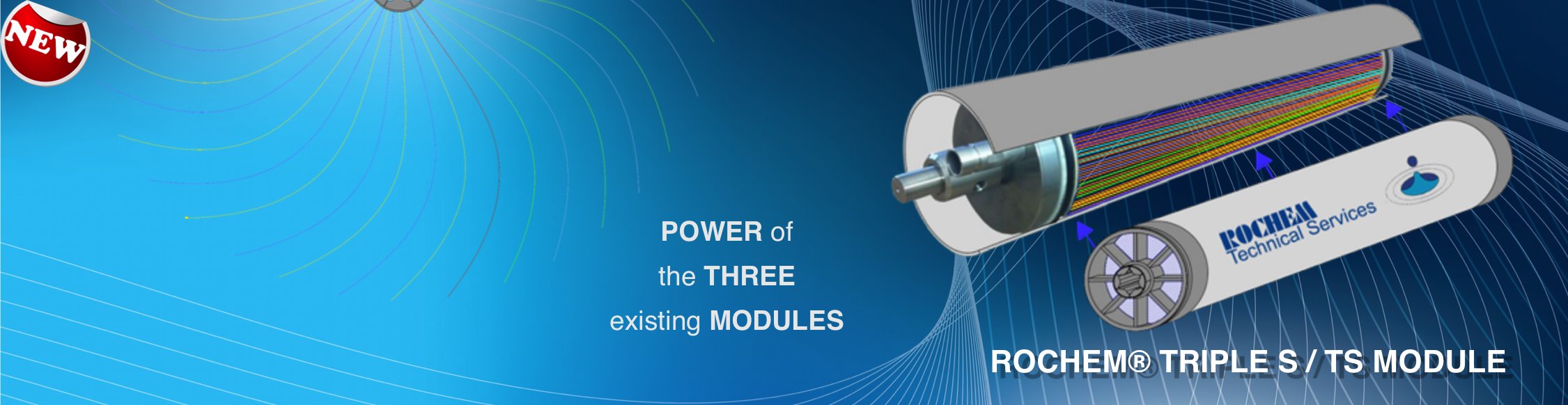

ROCHEM® Triple S/TS Module(NEW)

THIS IS NEW, developed by ROCHEM®

R.T.S. Rochem Technical Services Gmbh is able to create a module especially for your requirements.

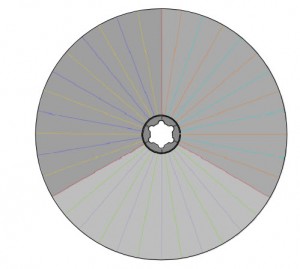

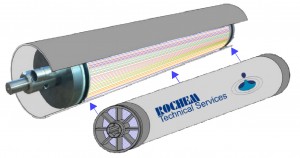

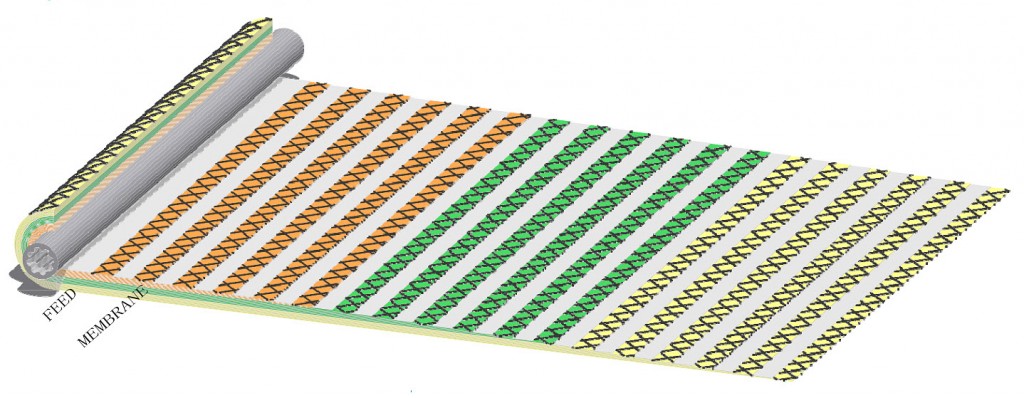

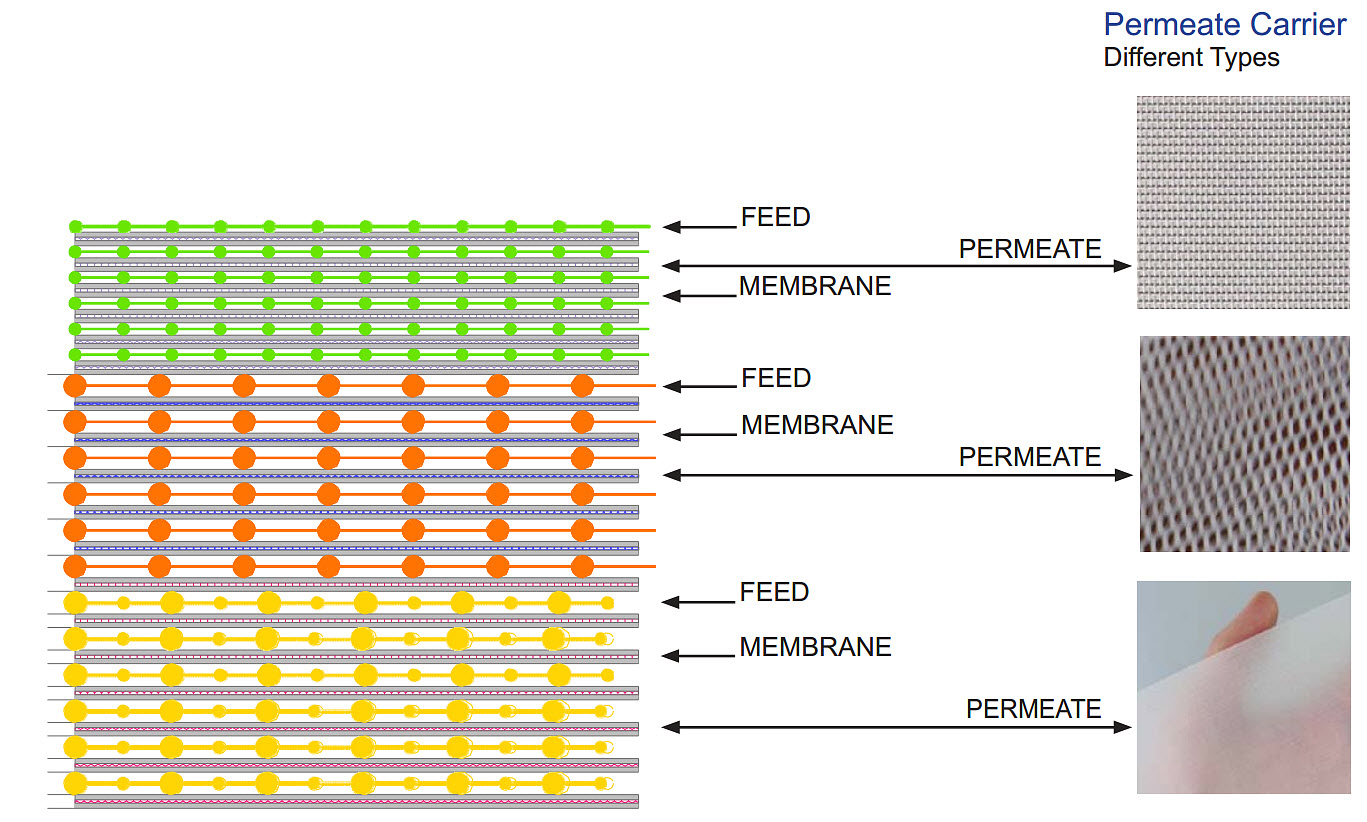

The significant difference to conventional spiral round modules is that R.T.S. Rochem Technical Services Gmbh combines different feed channels, permeate carriers and membranes in one module element.

The module element can be split in parts. Each part includes different feed spacers and membranes; also the membrane cushion carriers can be different. R.T.S. Rochem Technical Services GmbH has a lot of possibilities to find the ideal composition for your particular objectives.

MEMBRANE- Permeate Carrier – Membrane/Feed Spacer

Our standing:

Membrane Cushion

For different applications from different materials. The membrane cushion is made up with a sheet Known as the permeate carrier. This permeate carrier is sandwiched between two membranes. The outer diameter is sealed by ultrasonic welding of the three ore more sheets together.

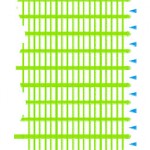

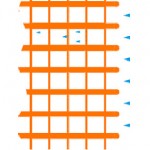

Different types and configurations/ open channel

Especially, this module includes 3 times membranes more than the existing modules so it has the power of the three existing ones

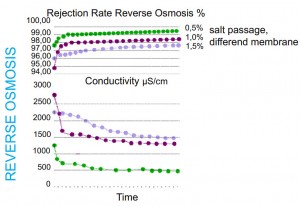

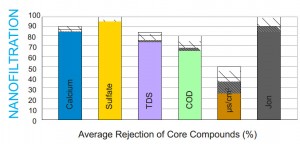

Rochem advanced reverse osmosis and nanofiltration processes significantly increase the permeate recovery rate and reduces the volume of concentrate. Depending on the chemistry of the untreated feed water, the volume of concentrate produced can be reduced by at least 50% from the volume of a single pass RO treatment, improving waste water management and reducing operating costs. The ROCHEM® Reverse osmosis and nanofiltration technology applied towaste water treatment is part of an envi- ronmentally friendly and sustainable treatment system.

The ROCHEM® reverse osmosis and nanofiltration membranes and the TS – elements provide a process that: – Is a careful and effective use of assets and resources – Minimizes the burden on the environment – Is commercially feasible and affordable.

The ROCHEM® “TS Triple S Modules“ are manufactured from the best and most sophisticated materials, for the customer ́s application. The pressure housing is made out of glass fiberup to 90 bar operating pressure and out of stainless steel up to 120 bar (316-316A). End flanges are made out of ABS, Ulfrem or stainless steel.